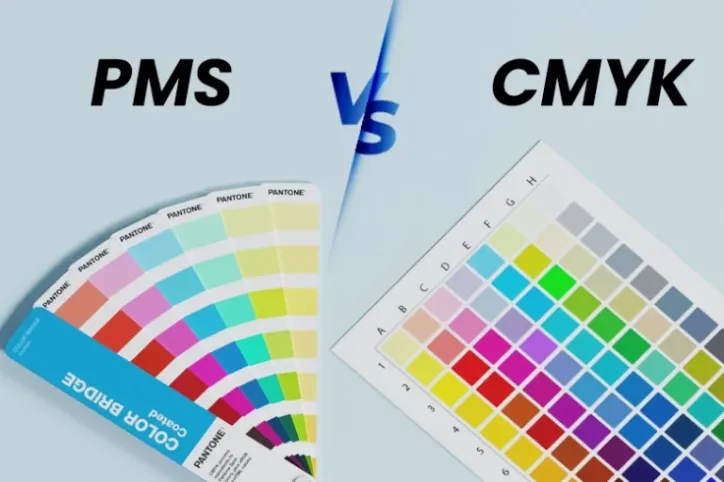

When it comes to printing, you surely want the result to be vibrant and captivating—whether it’s for brochures, product packaging, or other printed materials. PMS and CMYK are the most commonly used to achieve desired printing results.

What is PMS, what is CMYK, and what’s the difference between the two? Let’s explore every essential detail of the two options in this ultimate guide!

PMS Overview

The Pantone Matching System (PMS) is a universal color language that ensures precise color consistency across any printed material.

Pantone colors are pre-mixed inks (spot colors) that produce shades in brighter, more pigmented colors with crisp lines.

Even better, the Pantone Corporation has published swatch books to help you visually see and confirm how the ink will look when printed. Moreover, a Pantone color is identified by a code. For example, “coated” (C) paper, which provides a glossy finish and helps keep ink on the surface, or the (U) code for “uncoated” finish.

Pantone Colors

In Pantone print, each color uses a different ink. For example, if your project is PANTONE 286, PANTONE Red 032, and Black, it requires three colors. Simply put, for most instances, it would require three different printing plates.

How Does PMS Work?

PMS colors are identified by unique names and/or numbers, such as Ultimate Gray (#17-5104) and Illuminating (#13-0647).

The process itself creates colors that cannot be accurately replicated. Such color accuracy is essential when printing your business logo or trademark designs that require exact color matching. To achieve this, printing equipment must be prepped for each print job.

When to Use PMS?

Use the Pantone Matching System (PMS) for printed materials when precise, consistent color matching is essential for your business.

For example, your logo, branding, and specific brand colors should be printed identically across your custom packaging boxes and promotional items.

CMYK Overview

CMYK stands for Cyan, Magenta, Yellow, and Black (Key). This color model is used in printing processes in which four separate plates apply specific amounts of ink to create colors.

CMYK Colors

Printers use the four ink colors (Cyan, Magenta, Yellow, and Black), applied in a pattern of tiny dots. The process produces a wide range of colors for printed materials, such as magazines, brochures, and business cards.

Compared to Pantone standards, CMYK can lead to inconsistencies when replicating specific colors, especially vibrant blues, greens, and purples.

How Does CMYK Work?

CMYK inks absorb specific colors of light. Hence, the color we see is the light that is reflected. The process creates a wide spectrum of colors by varying the size and frequency of these dots in layers and at different angles. To avoid color shifting, always convert your digital RGB files to CMYK before sending them for print. Our RGB-to-CMYK guide explains the process step by step.

When to Use CMYK?

You can use the CMYK color process for all print projects, including business cards, brochures, signage, and custom packaging. Do note that this color model ensures accurate color reproduction.

What’s the Difference Between PMS vs CMYK?

Choosing between the PMS and CMYK color models can be pretty challenging. To make it easier, let’s break down the differences between the two with the table below.

| Feature | PMS | CMYK |

| Color Type | Spot colors (pre-mixed inks) | Processed colors |

| The Process | Each color uses a different ink that requires three different printing plates.

| Creates a wide spectrum of colors by varying the size and frequency of dots in layers and at different angles |

| Best for |

|

|

| Pros | Precise, consistent color matching | Ensures accurate color reproduction |

| Key Distinction | A specific color matches a unique ink number | Colors are created by a combination of four other colors |

| Cost | More expensive | Cost-effective |

How to Choose Between PMS and CMYK for Custom Packaging?

For some printed materials, reproducing an exact color is not a high priority. However, for branded materials, reproducing an exact color match is essential to the business identity.

Thus, if you’re considering PMS vs. CMYK for a custom packaging project, it depends on your packaging goals.

Best with PMS Printing

- Brand color consistency

Brands with a specific, recognizable color (like Tiffany & Co. or Coca-Cola) that must be reproduced identically on all packaging, every time.

- Limited-color designs

Simple designs that use only a few specific colors, such as a logo on a solid-colored background, on rigid boxes.

- Specialty colors

Designs that require metallic, neon, or pastel shades, such as holographic boxes.

- Luxury or premium products

Cosmetic boxes or jewelry boxes benefit from the vibrant, high-quality look that PMS colors provide for brand identity.

Best with CMYK Printing

- Packaging with images

Any design that includes realistic images, such as cereal boxes or food boxes featuring fruit, nuts, and other realistic food images.

- Complex, full-color designs

Detailed illustrations or designs that involve gradients and many colors, such as mailer boxes or display boxes.

Can We Convert Pantone Color to CMYK (Vice Versa)?

Converting PMS colors to CMYK and vice versa can be essential for maintaining color consistency. However, you should also understand how the colors will appear in different color spaces.

Pantone to CMYK

Converting Pantone colors to CMYK can be done using swatch books, software tools, or online converters. Do note that Pantone colors with complex blends may not have a direct CMYK equivalent, and some color shifting may occur during conversion. Thus, it’s always a good idea to perform a test print to ensure the desired results.

CMYK to Pantone

Converting CMYK colors to Pantone can be more challenging, as not all CMYK colors have a direct Pantone match. In such cases, the closer Pantone color you choose, the slight adjustments may be required to achieve a similar appearance.

Tips for Printing with PMS vs CMYK

Given the differences between PMS and CMYK, you can protect your branding and still address budget limitations. How?

Check out the tips below.

- Use the Tools

Many tools are available to convert Pantone colors to CMYK, completed with coatings such as Aqueous and UV.

- Discuss with Experts

In some cases, colors can differ on screen vs print. That’s why you should discuss with the experts, as they can advise on color selections and create a great match.

- Consider Your Purpose

Use PMS color printing for letterhead, business cards, packaging, and other printed pieces where an exact color is essential to the integrity of the branding.

Choose CYMK for print ads, brochures, and other multi-color items where slight variances won’t be as noticeable.

In brief, when you need branding and company identification with an exact color match, PMS color printing is the best choice. On the other hand, if you need slight color variations at a lower cost, CMYK is the way to go!

Summing Up

No doubt, both PMS and CMYK are the most commonly used to achieve desired printing results. Unique names and/or numbers identify PMS colors, while CMYK stands for Cyan, Magenta, Yellow, and Black (Key).

Pantone colors are best for brand color consistency, limited-color designs, and specialty colors. Meanwhile, CMYK printing is ideal for custom packaging with images and complex, full-color designs.

Nevertheless, hopefully, this ultimate guide helps you to choose the right one for your next printing or packaging project.

FAQs

What is PMS?

The Pantone Matching System (PMS) is a universal color language that ensures precise color consistency across any printed material.

What is CMYK?

CMYK stands for Cyan, Magenta, Yellow, and Black (Key). This color model is used in printing processes in which four separate plates apply specific amounts of ink to create colors.

Why should we use Pantone colors?

When you need branding and company identification with an exact color match, PMS color printing is the best choice.

What’s the main difference between PMS and CMYK?

The main difference is that PMS uses a pre-mixed ink formula for consistent, precise colors, while CMYK creates colors by mixing four ink colors—cyan, magenta, yellow, and black—on the press.