On-time Free Shipping Worldwide

Free Designing Support

100% Price Match Guarantee

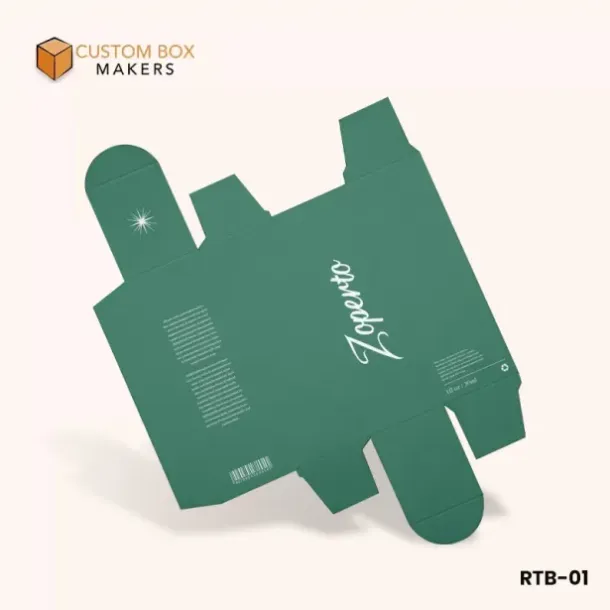

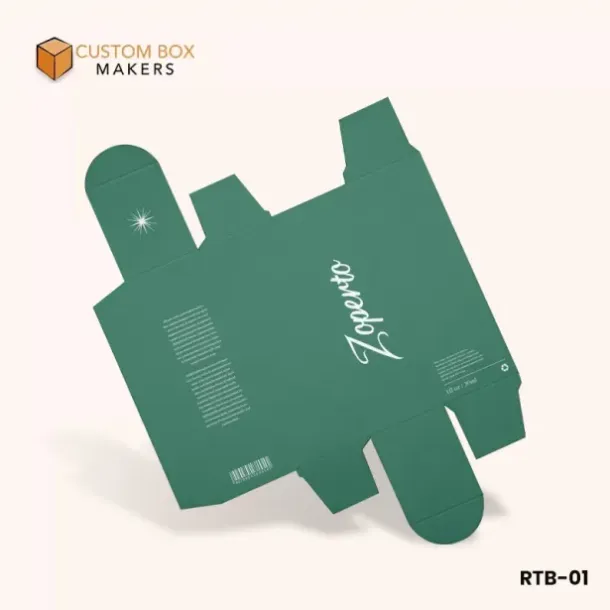

Our reverse tuck end boxes are designed for retail products that need secure, reliable, and elegant packaging. They are known by the name of reverse tuck end boxes in the market because of their unique construction.

The bottom panel folds in the opposite direction to the top, giving these boxes extra stability and ease to open without tearing. Fully customizable in size, color, design, and branding, our RTE cartons protect your products while creating a premium shelf presence for cosmetics, electronics, food items, and more.

Place your order today and let us help you create packaging that performs and proves to be a great choice.

Our custom reverse tuck end boxes are engineered to balance functionality and aesthetics, maintaining shape, protection, and professionalism. Built for light- to medium-weight products, these boxes feature top and bottom panels that fold in opposite directions. This mechanism ensures a secure closure without any extra adhesives.

Shipped flat for efficient storage and shipping, they assemble quickly, making them ideal for manual packaging or automated production lines. The smooth design and sturdy material choice allow you to print high-resolution graphics and logos and ensure they withstand repeated handling and stacking.

Reverse tuck end box packaging is ideal when it comes to offering your products a combination of protection, ease of handling, and a retail-ready appearance. These boxes also make sense for

Both reverse tuck boxes and straight tuck boxes are the favorites of retail packaging, but which one to prefer depends on the suitability of the product and the intended usage.

Products that move through multiple touchpoints, from packing to shipping to retail shelves, benefit from reverse tuck boxes.

Put your brand on the map with reverse tuck end boxes designed for versatility and impact. The custom reverse tuck boxes are ideal for a wide range of industries, including

Tailor your reverse tuck end cartons for both brand impact and product protection. Make every detail truly yours with

Adding this all-rounder packaging solution means you are investing in a scalable choice that will surely be a smart move. We ensure precision throughout the production, which maintains consistency in each piece.

Display your products in the best spotlight with our custom reverse tuck end packaging boxes that are built to impress. Personalize them with your logo, artwork, and window cutouts to create an unboxing experience that captivates customers.

Get benefit from our fast turnaround time and sustainable materials to align your brand with quality products. With no minimum order quantity, you can start small and scale up as your business grows.

Order now and ensure your products stand out on shelves while staying secure through shipping, handling, and display.

| Specification | Details |

|---|---|

| Box Style | Reverse Tuck End Boxes (RTE), Custom Tuck-End Styles |

| Dimensions (L × W × H) | Fully Custom Sizes & Shapes Available |

| Material Options | SBS Paperboard, Kraft Paper, Cardstock, Corrugated (optional), Recycled Paperboard |

| Material Thickness | 10 pt – 28 pt (60 lb – 400 lb) depending on product weight |

| Printing Options | CMYK, Pantone, No Printing, CMYK + 1 PMS, CMYK + 2 PMS |

| Coating Options | Gloss, Matte, Spot UV, AQ Coating, Soft-touch, Varnish, Lamination |

| Default Process | Die-Cutting, Scoring, Gluing, Perforation |

| Finishing Styles | Embossing, Debossing, Foil Stamping, Spot UV, Die-Cutting |

| Additional Features | Hang Tabs, Window Cutouts, Inserts, Tear Notch, Locking Tabs |

| Sampling Options | Flat View, 3D Mock-Up, Physical Sample (on request) |

| Proofing | Digital Proofs Provided Prior to Production |

| Turnaround Time | 8 – 10 Business Days (Rush Service Available) |

| Duration of Shipping | 2 – 3 Business Days (Free Delivery) |

| Minimum Order Quantity | No Minimum Order Required |

A durable and lightweight paperboard material. It can have a clay-coated surface on one or both sides for enhanced printability.

A strong and lightweight material with a fluted inner layer for added durability and cushioning. Perfect for shipping and product protection.

A strong, eco-friendly, unbleached kraft paperboard made from wood pulp. It has a natural brown color, making it ideal for sustainable packaging.

A shiny and vibrant finish that enhances color depth and contrast, making designs pop.

A water-based coating that adds a light protective layer and improves durability.

A smooth, non-glossy finish that offers a refined and elegant look. Reduces glare and enhances readability.

A velvety, premium finish that adds a luxurious feel while providing a subtle matte appearance.

A technique that creates raised or recessed designs, adding depth and texture.

A technique that creates raised or recessed designs, adding depth and texture.

A glossy coating applied to specific areas for contrast and visual appeal, enhancing details.

A die-cut opening that provides a sneak peek inside the packaging to enhance product visibility.

A metallic finish that adds a luxurious shine to logos, text, or designs for a premium look.

Read our customer’s reviews, which makes Custom Box Makers a trustworthy box manufacturer to rely on.

We’ve answered all the questions you might have before placing an order for a custom box. Have more questions? Feel free to contact us.

Reverse tuck end boxes are packaging boxes with tuck flaps on opposite ends—one folding in the front and the other in the back for secure closure.

They are typically made from cardboard, corrugated board, or kraft paper, depending on durability needs.

Yes, you can customize them with logos, colors, and designs to match your branding.

Yes, you can customize them with logos, colors, and designs to match your branding.

They are commonly used in cosmetics, retail, pharmaceuticals, and food packaging.

Yes, they can be tailored to any size based on your product dimensions.

They are commonly used in cosmetics, retail, pharmaceuticals, and food packaging.

Yes, they can be tailored to any size based on your product dimensions.