When it comes to sustainable packaging, one aspect that often goes unnoticed is the thickness of the material. This might make you think that it’s not as important as the design of the packaging, but it is. The thickness of your packaging material has a significant impact on protecting your product. It demonstrates the durability and aesthetic appeal of your packaging.

To manufacture effective packaging for your product, it is essential to understand the thickness of the packaging material. In this blog, we will examine the unit systems used in the packaging industry and discuss why the thickness of packaging is important.

But at first, let’s start by understanding what a GSM unit and a PT unit are.

What are GSM & PT Units?

The common terms that get used in the packaging industry for weight and thickness are GSM and PT. GSM stands for grams per square meter, whereas PT stands for point. Let’s learn about them deeply:

Grams Per Square Meter Unit

GSM indicates the weight of a sheet of paper or board based on its size. The GSM unit is primarily used when selecting rigid packaging stock. Higher GSM means thicker and stronger material that holds its shape well. Just because something looks thick doesn’t always mean it’s heavy. Take corrugated cardboard as an example; it may feel heavy or bulky, but it weighs less than some flat boards. GSM is used to demonstrate the real strength and durability, allowing you to obtain custom boxes that are both sturdy and solid.

The Point (PT) Units

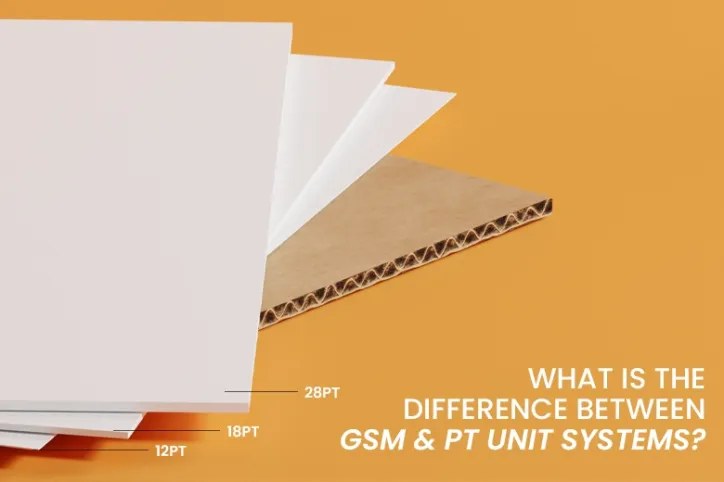

The point (PT) unit system is used to indicate the thickness of the material being used in manufacturing your packaging. The thickness of packaging materials, including corrugated cardboard, is measured by using vernier calipers, with each point showing as 1/1000th of an inch.

To check material thickness, you can browse our materials options guide. As you browse, you will see that the point system describes thickness as 8pt, 16pt, 18pt, up to 28pt.

The higher the PT, the thicker the material will be.

Importance of GSM Units in Packaging

GSM unit holds its importance for many various factors, such as:

- GSM is important as it is used more when communicating with the vendor.

- It helps in conveying information about the packaging material.

- The GSM has a significant impact on material costs.

- It provides a precise measurement for packaging thickness.

Common GSM Paper Measurements

If you understand the common GSM paper measurement, it will help you to make better decisions for your packaging.

You can choose the right thickness material based on your packaging by following the table below:

| GSM Paper Measurement | Purpose |

| 35-55 gsm | For printing the newspaper |

| 90-100 gsm | Normal printing paper for a copy machine |

| 120-140 gsm | Flyers and posters get printed with this paper |

| 210-300 gsm | Perfect for glossy brochures |

| 350-400 gsm or above | Mainly for packaging, business cards, and rigid boxes. |

Point (PT) Unit Conversion GSM Unit System

GSM is the metric system of the PT system. You can use this for calculating thickness. However, there is no direct way to calculate it. To make things easier for you, we have curated a table that will help you understand which GSM correlates with which PT.

| GSM | Approx. PT |

| 80–100 GSM | 4–5 PT |

| 120–150 GSM | 6–7 PT |

| 200 GSM | 10–12 PT |

| 250–300 GSM | 14–16 PT |

| 350–400 GSM | 18–20 PT |

| 500–600 GSM | 24–28 PT |

Apart from paper, there’s also corrugated board, which comes in various types, including single-face, single-wall, double-wall, and even triple-wall. Each type has its own GSM, giving you different levels of strength and durability.

Comparison Between GSM VS. PT System

We understand that measuring systems can be confusing between the US and metric systems. The one thing to remember is that the GSM system is used to indicate weight, whereas the PT system indicates the measurement of paper.

It is imperative to know the weight and thickness of your packaging material, as it is helpful when manufacturing corrugated paper or cardboard packaging. Additionally, the thickness and weight you choose for your packaging will help provide a great unboxing experience.

How GSM & PT Systems Shape the Quality of Your Packaging?

Now that you know how GSM and PT work, how do you implement them in your packaging? Start by looking at your material carefully during the design stage. The GSM helps you decide which stock will protect your product and how the final box will feel. Do you want packaging that feels solid and heavy or something light and easier to handle? If you’re printing images or logos, a higher GSM will give you a sharper quality and better-looking prints. Even the output of your final choice highly depends on the GSM and PT system.

Still unsure about the GSM and PT system? No worries, you can ask our expert at Custom Box Makers about it, and they will guide you with all your queries.

FAQs

What does GSM mean in packaging?

GSM stands for grams per square meter. It measures the weight of paper or cardboard, indicating the thickness and sturdiness of the packaging material.

What is the PT unit in packaging?

PT (point) is a unit that measures the thickness of paper or cardboard. One point equals 1/1000th of an inch.

How do GSM and PT differ?

GSM measures the weight of the material, while PT measures the thickness. Both are important for choosing strong, durable packaging.

How can I convert GSM to PT?

There is no exact formula, but reference tables can help. For example, 350–400 GSM roughly equals 18–20 PT.

Why is material thickness important for packaging?

Thicker materials offer better protection for products, enhance durability, and improve the overall look and feel of the packaging.

What GSM is best for packaging boxes?

For most packaging boxes, 350–400 GSM or higher is ideal as it provides strength and rigidity.

Can I ask for a custom thickness for my packaging?

Yes! At Custom Box Makers, you can consult our experts to choose the perfect thickness for your packaging needs.