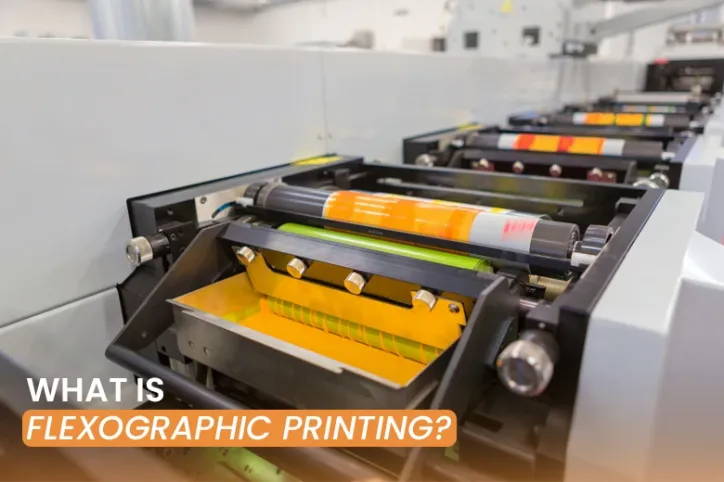

Flexographic printing is a high-speed rotary printing that uses flexible rollers and relief plates to print directly onto a variety of materials. It is one of the most preferred printing techniques in the packaging industry because it combines speed, versatility, and cost efficiency, which is ideal for both large-scale production and small packaging needs. Unlike traditional or highly advanced methods, flexography can print on paper, cardboard, plastic labels, foils, and even laminated substrates.

How does flexographic printing work?

The process of flexographic printing begins with the creation of photopolymer plates and undergoes different steps that work within seconds and print multiple substrates.

Design Preparation

The artwork you need printed is prepared digitally using creative tools and applications. This design will then be used to create a film or mask for the plate.

Plate Exposure

These photopolymer plates are then coated with a light-sensitive layer and exposed to UV light. The areas exposed to light harden, while the unexposed areas remain soft. After exposure, the soft areas are washed away, leaving a raised image. This part will pick up the ink and transfer it.

Mounting the Plate

Once the plate has finished carrying the design to be printed, it is mounted onto a plate cylinder in the printing press. This cylinder will be rotated continuously during the process.

Ink Transfer – Anilox Roller

Ink is not supposed to be applied directly to the plate from the fountain or reservoir. Instead, it first goes to the anilox roller. An anilox roller is a metal cylinder with thousands of tiny engraved cells. Each cell holds a precise amount of ink. There is a doctor’s blade that is present against the anilox roller and scrapes off excess ink that sits above the cell level.

Plate Cylinder

The plate cylinder receives the ink from the anilox roller. Only the raised image areas hold the ink; the recessed areas remain clean. The plate cylinder then rotates to print the inked design on the substrate.

Impression Cylinder

An impression cylinder is placed on the other side of the substrate. This cylinder provides support and pressure, ensuring that the ink transfers smoothly and evenly from the plate to the material. Without the impression cylinder, the printed design could be blurry or inconsistent.

Substrate Movement

The material being printed moves continuously between the plate cylinder and the impression cylinder. This can be a flat sheet or a roll, depending on the press design.

Drying the Ink

Flexo inks dry quickly via air drying, heat, or UV curing, depending on the type of ink. This rapid drying prevents smudging and allows the printed final substrate to go into the production line for assembly.

Finishing Steps

After printing, the material comes out and can be cut, folded, laminated, or coated as needed for its final packaging form.

In short, the process that seems complicated often occurs at very high speed, printing thousands of meters per hour.

- The photopolymer plate has a raised image that carries the ink.

- An anilox roller is dipped with ink and meters a precise amount.

- The doctor’s blade scrapes off excess ink from the anilox roller.

- The plate cylinder receives ink from the anilox roller and transfers it to the substrate.

- The impression cylinder supports the substrate to ensure even pressure.

- The drying system quickly sets the ink, enabling continuous printing.

Flexographic Printing Examples

Flexo printing is a highly used method whose results you can experience in your daily life. Some of its household or commercial examples include:

- Chip bags, candy wrappers, juice cartons, cereal boxes, paper bags, barcode labels, peel-off medication labels, and shrink sleeves.

- Gift wraps, napkins, paper towels, notebooks, sticky notes, envelopes, non-woven wipes, and diapers.

Materials Suitable for Flexographic Printing

Flexographic printing is considered a choice due to its versatility and ability to print on a wide range of materials, especially for packaging labeling.

Where minimalism is trending, this printing method is winning because its results are sharp and precise.

Unlike other printing methods that are limited to rigid surfaces, flexography can handle both porous and non-porous materials, giving it an edge.

- Paperboard and Kraft Paper: Standard printing substrates for retail boxes, booklets, and lightweight packaging. Smooth or coated paperboard is ideal for high-quality consumer packaging, such as cosmetics, pharmaceuticals, and printed food boxes.

- Corrugated Cardboard: Common in shipping cartons and e-commerce packaging. The flexible plates and high ink transfer capability allow vibrant designs even on textured surfaces.

- Plastic Films: Used in flexible packaging such as mylar bags, wraps, and laminates. Flexographic inks, including UV- or solvent-based, adhere well to non-porous films.

This substrate versatility enables flexography across a wide range of packaging formats, from small retail boxes to large industrial rolls, making it the go-to choice for multi-material packaging operations.

Benefits of Flexographic Printing

The versatility of flexographic printing makes it a practical choice for modern packaging, where label printing, intricate designs, and minimal artwork create maximum impact.

- It can print thousands of meters per hour, making it ideal for mass production.

- Prints reliably on paper, cardboard, plastics, foils, laminates, and other coated materials.

- Economical for long runs because plates last for tens of thousands of impressions, and ink usage is completely optimized.

- Maintains sharp text, solid color areas, and precise graphics, even in volume runs.

- Every detail is sustainable, from water-based, UV-curable inks that are also food-safe when certified.

- Handles both short and extremely long print runs with minor adjustments and tweaks to press setup.

- Printed materials are resistant to smudging, scratching, and fading when each step of the process is executed perfectly.

Limitations of Flexographic Printing

There are no second thoughts in considering flexo printing the most viable method that is convenient and efficient. However, flexible packaging printing has some limitations that affect certain applications such as

- Very fine photographic details or intricate gradients result in less precision, like the high-res details are sometimes not that sharp compared to offset or gravure printing.

- The initial setup and plate creation can take longer. The more colors, the more time will be required to prepare the plates.

- Some plastics or coated materials may demand specialized inks, coatings, or treatments to ensure proper adhesion, which is another substrate-specific challenge.

- Multi-color designs require precise adjustments and still may not achieve perfect color accuracy.

Comparing Flexographic Printing vs Other Printing Methods

To make an informed decision, it is crucial to compare flexography printing with other printing methods and choose the most suitable one based on the requirements of the project.

Flexo vs. Offset Printing

- Offset printing produces high-resolution images on flat, smooth surfaces, such as paper.

- Flexography can be done on flexible materials and absorbent and nonabsorbent substrates, too.

- Flexography is faster and more economical for long runs, particularly for packaging rolls and labels, and is not limited to any material or its surface texture.

Flexo vs. Digital Printing

- Digital printing allows short runs and customization without plates, allowing for less time consumption, and is suitable for variable data printing.

- Flexography is more cost-effective for long runs, with consistent quality and faster throughput.

- Digital printing is slower at scale and less suited for continuous roll-to-roll production.

Flexo vs. Gravure Printing

- Gravure delivers extremely high resolution and fine detail but involves higher plate costs and setup time.

- Flexography is more versatile and economical for medium- to long-run printing, and it is easier to adapt to different substrates.

- Gravure is primarily used for premium or specialty packaging that requires ultra-fine detail.

Each printing method is used in different applications, depending on the requirements. It is difficult to say which is better. However, all of them have their own benefits and drawbacks and have left behind traditional printing methods, which were costly and time-consuming.

Future Trends in Flexographic Printing

The continuous growth of the packaging and printing industries has driven further technological advancements. These advancements have allowed flexographic label printing to stay competitive and relevant in the market.

- Hybrid presses are being integrated into flexo machines to combine digital printing, making it easier to handle variable data, short runs, and plate setups.

- Increasing use of water-based and UV-curable inks for environmental and safety compliance, benefiting brands seeking sustainability across every sector.

- Automated ink controls, color management, and plate alignment will be improved with AI to improve efficiency and reduce errors.

- Innovations in coatings and biodegradable films enable flexo printing to adapt to a range of packaging materials, including other flat and hard surfaces.

FAQs

How many types of flexographic printing are there?

There are three main types of flexo printing that are classified by their physical layout and press configuration.

- Central impression (CI)

- In-line press

- Stack press

How does flexographic printing work step by step?

Flexographic printing works by transferring ink from an anilox roller to a raised photopolymer plate, which then presses the ink onto the substrate with the help of an impression cylinder. Excess ink is controlled by a doctor’s blade, and the printed material is dried immediately to allow continuous production.

What is an anilox roller in flexographic printing?

An anilox roller is a metal roller engraved with microscopic cells that measure and deliver a precise amount of ink to the printing plate. It ensures consistent ink coverage and accurate color reproduction during flexographic printing.

What is a photopolymer plate?

A photopolymer plate is a flexible printing plate created by exposing light-sensitive material to UV light. The exposed areas harden to form a raised image, which carries ink and transfers the design onto the substrate during printing.

Where is flexographic printing commonly used?

Flex printing is widely used for packaging boxes, corrugated cartons, flexible packaging, labels, mailer boxes, food packaging, and industrial wraps.

What industries rely on flexographic printing?

Industries that commonly use flexographic printing include food and beverage, e-commerce, retail, pharmaceuticals, cosmetics, personal care, and industrial packaging.

What types of inks are used in flexographic printing?

Flexographic printing uses water-based, solvent-based, and UV-curable inks.

What are the main advantages of flexographic printing?

Flexographic printing offers high-speed production, material versatility, cost efficiency for long runs, consistent quality, and fast ink drying, making it ideal for large-scale packaging and labeling.

How many cylinders are used in flexographic printing?

Flexographic printing typically operates with four cylinders.

Ink Fountain Roller: Picks up and supplies ink to the printing system.

Anilox Roller: Controls and measures the exact amount of ink.

Plate Cylinder: Holds the printing plate and carries the image.

Impression Cylinder: Presses the material against the plate for clean printing.

Why is flexographic printing preferred for packaging?

Flexographic printing is preferred for packaging because it can print on many materials, handle high volumes, dry quickly, and maintain consistent print quality, making it suitable for commercial and industrial packaging needs.